New Standard | Analysis of GB 24541-2022 “Hand Protection Mechanical Hazard Protective Gloves”

GB 24541-2022 “Protective gloves for hand protection against mechanical hazards”

GB 24541-2022 “Protective gloves for hand protection against mechanical hazards”

The second half of 2023 is the transition period between the old and new standards. Compared with the old standards, what are the differences and changes in the new standards? Let’s take a look at the modified parts of the new version of the standard for better implementation in the future.

Update 2: Terms and Definitions

Update 2: Terms and Definitions Update Three: Technical Requirements

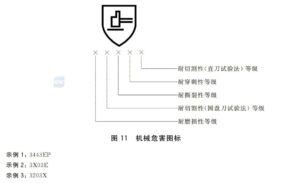

Update Three: Technical Requirements-

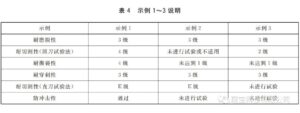

Added requirements for cutting resistance performance levels based on the straight knife test method in the general protection requirements -

Added impact protection requirements and impact resistance test methods -

Added test method for cutting resistance (straight knife test method) - Added requirements for abrasion resistance, cutting resistance (disc knife test method), and tear resistance test reports

-

Added normative requirements for abrasives and verification tests for double-sided tapes

Click to download the standard(Chinese Version)

Click to download the standard(Chinese Version)

Statement:

The pictures in this article are from the Internet, and the copyright belongs to the original author. This official account is a learning and communication platform and is not used for commercial purposes. If there is any infringement, please inform us in time and delete it after verification. The content is the author’s personal opinion and does not mean that this official account agrees with his/her views. This is for learning and reference purposes only, and no guarantee is made as to the accuracy, reliability or completeness of the information; contact/contribution cooperation: [email protected]