Key elements of the thermal injury gloves standard: GB/T 38306-2019 analysis

Hands are one of the main tools of the human body, and protecting them is essential for modern workers. However, how to correctly select hand protection products and evaluate their performance has always been a challenge in the field of hand protection.

Hands are one of the main tools of the human body, and protecting them is essential for modern workers. However, how to correctly select hand protection products and evaluate their performance has always been a challenge in the field of hand protection.

To solve this problem, EU Directive 89/686EEC divides personal protective equipment (PPE) into three categories, and thermal protection gloves belong to Class III products for defending against extremely high risk injuries. Their certification procedures are quite strict and must comply with the corresponding European standards, namely EN407 “Gloves for thermal protection (heat and/or fire)”.

my country’s National Standardization Association also issued the national standard GB/T 38306-2019 “Hand Protection – Heat Protection Gloves” in 2019, which modified and adopted the technical content of the EN407:2004 version to improve the standard system of hand protection equipment and adapt to protective applications in the domestic market.

Physical Testing

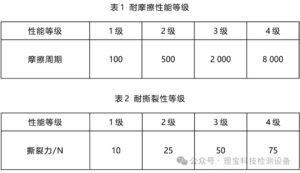

The standard includes two mechanical test requirements for friction resistance and tear resistance based on “GB 24541-2009 Hand protection gloves against mechanical hazards”.

The friction resistance is characterized by the number of cycles when the sample is damaged. Damage refers to the appearance of a hole through the test sample. It is required to be tested for at least 100 cycles before damage, which is the level 1 requirement. Tear resistance is defined as “the force required to tear a rectangular sample with half of the length open. The standard stipulates that the glove material (mm) must be tested and persist at least 10N, which should meet the level 1 performance requirements.

In addition, requirements are also put forward for the structure of gloves (take off in seconds). Gloves with thermal protection performance levels of 3 and 4 should be able to be easily taken off in an emergency. When tested according to the prescribed method, the time to take off the gloves shall not exceed 3 seconds.

Thermal protection performance

GB/T 38306 specifies six thermal properties, each with four associated performance levels, from Level 1 to Level 4. Depending on the form of thermal damage that may be exposed in the intended application area of the gloves, the gloves should meet one or more of these performance requirements. This standard provides performance levels rather than protection levels.

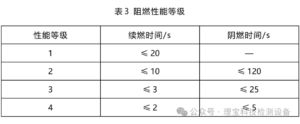

- Flame retardant properties

The flame retardant test is used to evaluate the ability of the glove to protect the wearer’s hand when it is close to an open flame. In order to achieve good results in the test, the gloves do not need to be flammable, but must inhibit combustion and burn slowly. In the test, the entire glove sample is placed vertically on the test burner, and the open flame burns vertically at a distance of 20±2 mm from the middle fingertip. The requirements for afterflame time and smoldering time must be met at the same time, at least level 1. The entire glove is tested, there should be no molten dripping, and the seamed part cannot be torn 15s after ignition.

- Afterflaming time: refers to the time that a material continues to burn with flame after the ignition source is removed under specified test conditions.

- Smoldering time: refers to the time that the material continues to burn flamelessly after the ignition source is removed or the flaming combustion stops.

If melting occurs, there should be no dripping of the material, no signs of melting in the innermost layer of the glove, no holes in all layers in the test area, and no cracks in the seams. (Melting refers to the softening and flow of a material at high temperatures; dripping refers to the separation of molten droplets of a material during the melting process)

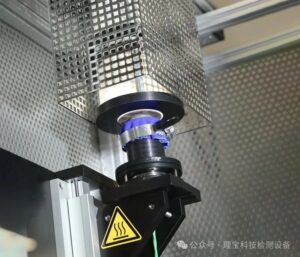

Test Equipment:

Vertical flame spread analyzer

-

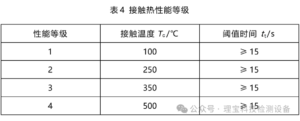

- Contact heat

Heat is transferred within and through the physical body by conduction. The amount of heat transferred during conduction depends on many factors – surface area, actual temperature of the hot object, conductivity and heat capacity of the glove and object, and pressure at the contact point. For example, a hot cup of coffee at 70-80°C will easily bubble up because its contact pressure is high. In contrast, sparks from a grinder, despite being 1000°C -+ , are barely noticeable because the contact pressure is light and the object is very small with a low heat capacity.

The heating column is heated to the contact temperature and maintained at the contact temperature, and the sample is placed on the calorimeter. The heating column is lowered to the sample supported by the calorimeter, or the calorimeter and the sample are lifted to the heating column. Either operation should be performed at a constant speed. The threshold time t t is determined by monitoring the temperature of the calorimeter . When the gloves are exposed to heat sources of 100℃, 250℃, 350℃, and 500℃, the time required for the internal temperature of the gloves to rise by 10° is greater than or equal to 15s, which is considered qualified.

Contact temperature refers to the constant surface temperature of the contact area of the heating tube in this test; threshold time refers to the time required for the calorimeter temperature to rise by 100°C in this test; when the contact heat performance is level 3 or level 4, the flame retardant performance should reach at least level 3.

Contact Thermal Analyzer

- Convection heat

Figure 3 : Convection heat test

Figure 3 : Convection heat test

Convection Thermal Analyzer

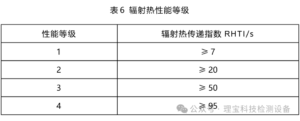

- Radiant Heat

According to the test method, it is carried out on samples supported by independent frames and exposed to specific radiant heat levels (Figure 4). When tested at a specified incident heat flux density, the average time (seconds) for the temperature rise of the calorimeter to reach (24±0.2)°C is recorded and expressed as a radiant heat transfer index. The percentage of the heat transfer coefficient is calculated based on the temperature rise data. The radiant heat performance level can only be reported when the flame retardant performance reaches level 3 or 4.

Radiation Thermal Analyzer

- A small amount of molten metal splashes

The molten metal droplets of specified size (0.5g) are used to hit the outer surface of the glove at a specified rate, so that the sample temperature rises to 40°C, and the number of molten metal drops is used to determine. The performance level can only be reported when the flame retardant performance reaches level 3 or 4. Level 1 requires that the fabric can withstand the impact of at least 10 drops of molten metal.

Molten Metal Drop Impact Analyzer

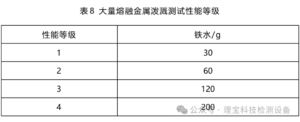

- Large amounts of molten metal splashing

Figure 6 : Large amount of molten metal splashing test

If the molten droplets remain on the specimen or the specimen is ignited or burned, it is unqualified. Other metals should be selected for testing as needed, and the corresponding test results should be given in the information provided by the manufacturer.

Large molten metal splash analyzer

The marking shall comply with the requirements of GB/T 12624 and Chapter 6 of GB 24541-2009, and shall be represented by a flame pictogram and six performance level numbers, as shown below. If the performance level is marked as X instead of a number, it means that the glove does not have that performance.

Conclusion

Industrial operation scenes are complex, and different types of gloves have their specific performance and uses. In actual work, they must be used and distinguished correctly in combination with the operating conditions. Good hand protection is safe and can reduce work-related accidents and improve production efficiency.

Not every job requires gloves with the highest level of thermal protection, so when dealing with extreme heat, flames or molten materials, it is important to understand the different glove combinations. Test standards GB/T 38306 and EN 407 provide manufacturers and users with intuitive parameters for glove material properties and specifications – because when heated, not all gloves are the same in terms of heat and flame resistance.

The German company Wazau produces and designs a series of thermal protection equipment to provide fast, accurate and highly repeatable test data. To prevent accidental injuries to operators, the instrument is equipped with fire and heat protection fences. The automatic test function of the instrument can be used to perform tests with the fence closed, and the parameters can be set, analyzed and stored more carefully through the software.

Libero can provide a series of high-precision and high-quality cold-proof glove testing equipment. Welcome to contact us~

Read the original article: Key elements of the thermal injury gloves standard: GB/T 38306-2019 analysis

Statement:

The pictures in this article come from the Internet, and the copyright belongs to the original author. This official account is a learning and communication platform and is not used for commercial purposes. If there is any infringement, please inform us in time and delete it after verification. The content is the author’s personal opinion and does not mean that this official account agrees with his/her views. This is for learning and reference purposes only, and no guarantee is made as to the accuracy, reliability or completeness of the information; contact/contribution cooperation: [email protected]