While the human body can normally regulate skin and core temperature through responses such as sweating, it quickly loses the ability to retain heat in extremely cold conditions, with heat flowing through clothing into the frigid atmosphere.

Cold weather protection is primarily a matter of reducing heat loss to keep the body warm. Normal core body temperature in a healthy person is 37°C, with skin temperature around 34°C. At lower ambient temperatures, we quickly begin to feel uncomfortable, even though core body temperature will initially remain constant.

Any deviation from core body temperature is serious and can cause serious problems for the human body. “Hypothermia” is any condition in which the body’s temperature drops below the level required for normal metabolism or bodily functions to occur. The human body’s core temperature is maintained at or near a constant level through biological homeostasis. When the body is exposed to cold, its internal mechanisms may not be able to replace the heat lost to the surrounding environment. The result is more than just feeling cold; a drop in body temperature of several degrees can severely affect brain function and impair judgment.

Heat loss in extreme cold conditions

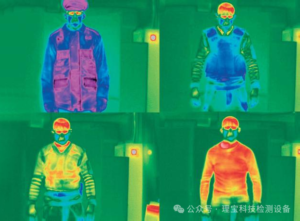

Air is a very effective insulator, and many garments rely on trapping a layer of still air to prevent heat loss. Because water is a good conductor of heat, it is a poor insulator. Moisture accumulates inside clothing due to sweating—especially when the wearer is physically active. This doubles the amount of heat lost through the garment, as the insulating properties are reduced (see Figure 1).

Figure 1: Thermal camera image showing how reducing insulation (clothing layers) increases heat loss (red)

Moisture trapped in a material doubles the material’s thermal conductivity. Using breathable materials or films can reduce moisture levels – however, this also increases heat loss. Moisture evaporates, and in subfreezing conditions, where ambient humidity is close to zero, evaporation occurs very quickly. While beneficial for staying dry, a significant amount of heat is lost in the evaporation process. Heat loss from moisture is exacerbated by a property commonly known as “wind chill.” Moisture loss from the body in still air tends to slow down when the air around the body becomes saturated and forms a boundary layer. The body relies heavily on this boundary layer of still air to insulate against heat and cold.

In fact, many animals have hair or fur to help protect this layer. Air movement removes this saturated layer, replacing it with dry air, which increases the rate of evaporation. The greater the wind speed, the greater the evaporation rate and heat loss. In an air temperature of 0°C, a wind speed of 50 km/h will make it feel colder than standing in still air at -20°C.

Whatever high-performance material is used, openings must be provided for the limbs, neck, and head. In addition to requiring good insulating properties, a garment must also trap a layer of air between itself and the body. Any garment must maintain this layer to be effective. No amount of insulation can prevent heat loss if this trapped air is allowed to exchange with the air in the environment. Openings must be carefully designed and provided with effective closures to retain the trapped air and prevent drafts.

When testing cold weather clothing, it is important to understand the materials used and how the entire garment will perform. Durability is important and tests such as flex cracking at low temperatures will show the suitability of the material. Breathability is also an important property if the garment is designed to be windproof.

The temperature of the extreme cold garment testing environment chamber can be varied from -40°C to +50°C, and the humidity from 5% to 95% relative humidity (RH) above freezing. Full garment testing can be performed in two ways. The first method uses a mannequin that is preheated to a known temperature (usually 32°C). The mannequin is dressed in the test garment and equipped with a thermocouple so that the “skin” temperature can be monitored. The clothed mannequin is then placed in the cold environment and the time it takes for the “skin” to cool to the set temperature is measured.

Extreme cold weather clothing testing environment chamber, temperature can be changed between -40°C and +50°C

The second method is to use human subjects, who are monitored by measuring skin temperature (for safety) and questionnaires about the subject’s comfort and warmth. The subjects can also perform a number of different tasks to simulate physical activity. The performance of the garment under these conditions can only be measured by using human subjects. Mannequins are particularly useful in cases where testing involves prolonged periods of extreme cold or where it is simply not possible to use human test subjects.

Extreme cold weather clothing testing environment chamber, temperature can be changed between -40°C and +50°C

The second method is to use human subjects, who are monitored by measuring skin temperature (for safety) and questionnaires about the subject’s comfort and warmth. The subjects can also perform a number of different tasks to simulate physical activity. The performance of the garment under these conditions can only be measured by using human subjects. Mannequins are particularly useful in cases where testing involves prolonged periods of extreme cold or where it is simply not possible to use human test subjects.

test instrument:

Standard laboratory tests are regularly performed to assess the air permeability and permeability of materials. For control and repeatability, these are performed under standard laboratory conditions (usually 20°C and 65%RH, or 23°C and 50%RH).

These permeability tests can be applied to products in various environments and industries, from outdoor mountaineering cold-proof clothing to cold-proof clothing for employees working in low-temperature environments, to cold-proof clothing for the military and police, plateau border defense, and even to cold-proof clothing for aerospace use, to evaluate indicators such as windproof and breathable, waterproof, cold-proof and warm, moisture permeability, and thermal comfort of single fabrics or entire garments.

Textest Automatic Hydrostatic Head Tester

Evaluating waterproofness and deciphering the “all-weather response strategy”

Textest Automatic Hydrostatic Head Tester

Evaluating waterproofness and deciphering the “all-weather response strategy”

Textest Air Permeability Tester

Evaluating wind resistance and understanding “wind cooling”

Textest Air Permeability Tester

Evaluating wind resistance and understanding “wind cooling”

Textest Water Vapor Transmission Rate Tester

Evaluate the moisture permeability and sweat wicking ability to solve the problem of hypothermia and frostbite caused by poor sweat (wetness) wicking

Textest Water Vapor Transmission Rate Tester

Evaluate the moisture permeability and sweat wicking ability to solve the problem of hypothermia and frostbite caused by poor sweat (wetness) wicking

PT Teknik Sweating manikin

Evaluate thermal and moisture resistance of clothing and other thermal comfort performance. Evaluate the moisture permeability of shoes and clothing from the perspective of human body heat dissipation

Fabric technology is constantly advancing and many innovative materials have been developed over the years. While these products can be tested under standard conditions, their true performance benefits and actual use may only be seen after they are challenged in extreme conditions.

PT Teknik Sweating manikin

Evaluate thermal and moisture resistance of clothing and other thermal comfort performance. Evaluate the moisture permeability of shoes and clothing from the perspective of human body heat dissipation

Fabric technology is constantly advancing and many innovative materials have been developed over the years. While these products can be tested under standard conditions, their true performance benefits and actual use may only be seen after they are challenged in extreme conditions.

Testing under extreme conditions through precision and high-quality equipment can detect and evaluate materials under real working conditions, provide more accurate actual application data, and assist in research and development and process improvement.

Read the original article: Fighting against ice and snow – How do extreme cold clothing cope with extreme low temperatures?

Statement:

The pictures in this article come from the Internet, and the copyright belongs to the original author. This official account is a learning and communication platform and is not used for commercial purposes. If there is any infringement, please inform us in time and delete it after verification. The content is the author’s personal opinion and does not mean that this official account agrees with his/her views. This is for learning and reference purposes only, and no guarantee is made as to the accuracy, reliability or completeness of the information; contact/contribution cooperation: [email protected]

Extreme cold weather clothing testing environment chamber, temperature can be changed between -40°C and +50°C

Extreme cold weather clothing testing environment chamber, temperature can be changed between -40°C and +50°C