Explore GB/T 21295-2024: New Specification for Physical and Chemical Properties in the Apparel Industry

GB/T 21295-2024 “Technical Requirements for Physical and Chemical Properties of Clothing” was released on March 15 and is scheduled to be officially implemented on October 1. This standard replaces GB/T 21295-2014 and updates and supplements the technical requirements for physical and chemical properties of clothing products.

This will help improve the quality of clothing products and ensure the safety and comfort of consumers. For clothing manufacturers, it is necessary to adjust production processes and materials to ensure that products can meet the requirements of the new standards. The implementation of the new standards will promote the development of my country’s clothing industry and provide consumers with better product choices.

The requirements for color fastness to wet rubbing, color fastness to light and color fastness to hot pressing have been changed; the requirements for color fastness to storage, color fastness to staining with detergent, color fastness to yellowing from light and color fastness to ozone have been added; the requirements for dye migration performance and color fastness to washing with soap for sewing threads, decorative threads and embroidery threads have been deleted; and the provisions in the footnotes have been changed.

The requirements for seam slippage degree, seam strength, pilling performance, tear strength, breaking strength, adhesive lining peeling strength, and abrasion resistance have been changed; the requirements for bursting strength and resistance to moisture and heat aging have been added.

In particular, the phenomenon of yarn slippage and fabric breakage in the seam strength test is judged as unqualified. When the finished product has fabrics with different unit area masses, the technical requirements of the one with lower unit area mass are selected: When the fabric and lining are joined together, the technical requirements are selected based on the sum of the unit area masses of the fabric and lining.

Tear strength is only tested on fabrics; elastic fabrics are not tested.

It is clarified that cashmere fabrics are goat cashmere fabrics, which have been expanded to include technical requirements for semi-worsted wool fabrics and their blended fabrics, and semi-worsted goat cashmere fabrics (with a cashmere content of 30% or more). It is particularly pointed out that elastic fabrics will not be assessed.

The mass of water vapor that passes vertically through a unit area of fabric within a specified time while maintaining specified temperature and humidity on both sides of the fabric, measured in grams per square meter hour [g/(m 2 ·h)] or grams per square meter 24 hours [g/(m 2 ·24h)].

The moisture permeability requirement should be no less than 2 200 g/(m 2 ·24h).

Test Equipment:

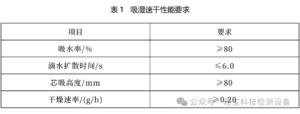

2.2 Moisture absorption and quick drying performance

2.2 Moisture absorption and quick drying performance

GB/T 21295-2024 does not set separate requirements for hygroscopicity and quick-drying performance, changes the evaporation rate to the drying rate, and deletes the moisture permeability requirement.

-

Water absorption rate: The percentage of water absorbed by the fabric to the original mass of the fabric when the fabric is completely soaked in water and then taken out until no water drips. -

Water drop diffusion time: When water is dropped on the fabric, the time required from the time the water drop contacts the sample to the time it completely diffuses and penetrates into the fabric. - Wicking height: A measure of the capillary effect of a textile material, that is, the height to which water rises along the textile material within a certain period of time through capillary action when one end of a vertically suspended textile material is soaked with water.

-

Drying rate: refers to the evaporation of water in the sample per unit time.

The parameters of various indicators have also changed:

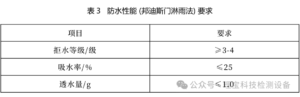

2.3 Waterproof performance

GB/T 21295-2024 pays more attention to selecting evaluation methods based on the specific usage scenarios of the product. Different methods have specific requirements before and after washing.

“Water repellent” refers to the ability of a fabric to resist absorbing sprayed water. “Waterproof” refers to the ability of a fabric to resist being wetted and penetrated by water.

a. Water dipping method:

The water level should not be lower than level 3-4 before washing and should not be lower than level 3 after washing.

b. Hydrostatic pressure method:

The ability of a fabric to resist liquid water penetration is expressed by the hydrostatic pressure that the fabric bears.

The hydrostatic pressure resistance before and after washing should meet the requirements:

c. Horizontal spray rain method:

The amount of water seepage before and after washing should not exceed 10 g.

d. Bondis Gate Rain Method:

The requirements should be met before and after washing:

Refers to the ability of clothing to resist or prevent the wearer’s body heat loss in low temperature environments. Common testing indicators include thermal insulation rate, thermal conductivity, thermal resistance, etc.

GB/T 21295-2024 requires that the thermal insulation rate of filled clothing should be no less than 68%; the thermal insulation rate of other clothing should be no less than 30%.

Refers to the protective ability of fabric to prevent itself from being ignited or to slow down and stop burning after contact with flames or hot objects.

The damaged length should be no more than 150 mm, the afterburning time should be no more than 5 s, the smoldering time should be no more than 5 s, and there should be no melting or dripping.

Test Equipment:

It refers to the cool feeling that occurs when the skin touches a fabric that is lower in temperature than the skin, causing the skin surface to lose heat quickly and the temperature to drop instantly. This feeling is then reflected to the brain through the temperature-sensitive nerve endings in the skin. It is usually characterized by the contact coolness coefficient (q max ).

The contact cooling coefficient (q max ) should be no less than 0.15 J/(cm 2 ·s)

Test Equipment:

Refers to the ability of materials to withstand static electricity interference and prevent static electricity. The evaluation indicators of electrostatic performance of textile products include: resistance indicators (volume specific resistance, mass specific resistance, surface specific resistance, leakage resistance, inter-electrode equivalent resistance, etc.), electrostatic voltage and its half-life, charge surface density, etc.

The charge should not exceed 0.60 µC/piece.

2.8 Anti-electromagnetic radiation performance (new)

Electromagnetic shielding: The energy of electromagnetic waves is reflected or absorbed by the surface of the material, thereby hindering or reducing its propagation.

GB/T 21295-2024 requires that the electromagnetic shielding effectiveness should be no less than 5 dB.

Refers to the ability of a fabric to be easily cleaned of dirt by ordinary washing or wiping methods after it has been contaminated.

The new standard provides more detailed classification and rating, and puts forward specific requirements for the color difference level of the test results based on the initial color difference.

When the initial color difference is ≤3 levels, the color difference level of the test result should be ≥3-4 levels. When the initial color difference is ≥3-4 levels, the color difference level of the test result should be >0.5 levels of the initial color difference.

2.10 Anti-ultraviolet performance (no change)

The UV protection factor (UPF) should be greater than 40 and the T (UVA) AV less than 5%

2.11 Oil repellency (no change)

Oil repellency level should not be less than level 4

2.12 Easy-to-iron performance (new)

It refers to the ability of textiles to meet the requirements of daily life in terms of appearance smoothness, pleat appearance, seam appearance and dimensional stability after washing and drying without ironing.

After washing and drying 5 times, the appearance smoothness after washing and drying should be no less than level 3.5, the appearance smoothness of the seams after washing and drying should be no less than level 3, and the appearance of the pleats after washing and drying should be no less than level 3.

2.13 Anti-wrinkle performance (new)

The wrinkle level should not be less than level 3.

2.14 Some other features (new)

In terms of health care, requirements for anti-itching performance, anti-mosquito performance, anti-mildew performance, anti-mite performance, anti-bacterial performance, and deodorization performance have been added, as follows:

Read the original article: Explore GB/T 21295-2024: New Specification for Physical and Chemical Properties in the Apparel Industry

Statement:

The pictures in this article come from the Internet, and the copyright belongs to the original author. This official account is a learning and communication platform and is not used for commercial purposes. If there is any infringement, please inform us in time and delete it after verification. The content is the author’s personal opinion and does not mean that this official account agrees with his/her views. This is for learning and reference purposes only, and no guarantee is made as to the accuracy, reliability or completeness of the information; contact/contribution cooperation: [email protected]