How are high-visibility products evaluated? Learn more about the testing standards

The use of personal protective equipment (PPE) increasingly emphasizes the nature of the risk environment in which the product is used. High visibility garments are suitable for use in high risk environments, such as road workers and emergency response personnel in environments with high speed vehicle traffic.

High-visibility clothing is designed to make the wearer visible to the operator of a vehicle or other mechanized equipment in daylight conditions and conspicuous in dark conditions in all lighting conditions.

EN ISO 20471: 2013+A1: 2016 High visibility clothing – Test methods and requirements

EN 17353: 2020 Protective clothing for medium risk areas – Enhanced visibility devices – Test methods and requirements

ANSI/ISEA 107: 2020 High Visibility Safety Clothing

RIS-3279-TOM-2019 High Visibility Clothing

GB/T 26377: 2010 Retroreflectometer

GB/T 18833: 2012 Road Traffic Reflective Sheeting

GB 20653: 2020 Protective clothing – Occupational high visibility warning clothing

GB/T 28468: 2012 Traffic safety reflective school uniforms for primary and secondary school students

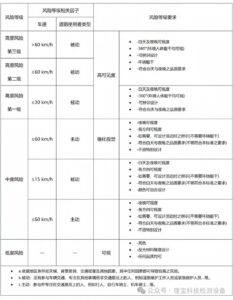

The EN ISO 20471:2013+A1:2016 standard specifies clothing that makes the wearer visible in high-risk situations. Given the importance of addressing the risks that high-visibility clothing or enhanced visibility products are used to address, Annex A of the EN ISO 20471 standard can be used to guide those sourcing the product that is most appropriate to address a specific risk situation.

Reference: BS EN ISO 20471:2013+A1:2016 Annex A, Road risk assessment levels

Most will choose to provide garments that comply with EN ISO 20471, keeping site workers protected in all conditions, whether working on motorways, adjacent roads or embankments, or in storage facilities, loading bays or docks.

With the popularity of night running, cycling and road fitness, safety protection equipment suitable for these scenarios has gradually become a necessity, and non-professional visual clothing/accessories have begun to receive more and more attention.

Different clothing standards allow for different colors of fluorescent materials. Clothing that complies with EN ISO 20471 must be yellow, orange-red or red fluorescent . The chromaticity of a color must be within the color space specified in the individual standards. Materials that will be used in clothing must be able to maintain compliance with color specifications after exposure in a xenon artificial light fading test. Similarly, materials must meet color retention requirements when subjected to wash tests on garments that can be washed.

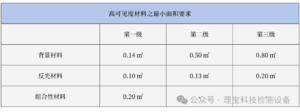

All standards include minimum area requirements for visibility materials to be included in the structure. The standards also set basic requirements for how to use reflective and fluorescent materials around the body, such as around the torso and limbs, to achieve effective visibility, with 360° visibility.

EN ISO 20471:2013+A1:2016 Minimum area requirements for high visibility

EN ISO 20471:2013+A1:2016 Minimum area requirements for high visibility

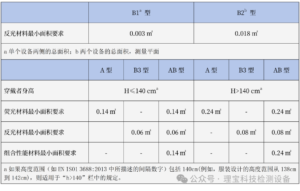

EN 17353:2020 Minimum area requirements for high visibility

Logo

The EN ISO 2047 standard divides high visibility into three levels based on the high risk level requirements in road risk assessment. The “X” value next to the high visibility logo represents the rating number against which the measurement results are compared.

The EN 17353 standard divides product designs into three categories according to foreseeable environmental conditions, and the corresponding marking requirements are as follows:

-

Type A – Daylight conditions, this type of equipment only uses fluorescent materials to enhance visibility; - Type B – dark conditions, this type of equipment only uses reflective materials to enhance visibility;

Type B1: Free hanging device Type B2: Temporary or permanent reflective devices worn on the limbs Type B3: reflective device worn on the torso or torso and limbs - Type AB – Daylight and dark conditions, this type of equipment uses fluorescent and reflective and/or combined functional materials to enhance visibility;

other requirements

As an important safety protection equipment, high-visibility clothing has very strict testing content and product design requirements. Visibility is as important as the use of color, which can be seen from the types of information signs used on the road. There is a difference between warning signs and ordinary information or advice signs. Only by meeting the requirements of the standard can it be guaranteed to provide adequate protection and comfort in actual use and reduce the risk of accidents.

Read the original article: How are high-visibility products evaluated? Learn more about the testing standards

Statement:

The pictures in this article come from the Internet, and the copyright belongs to the original author. This official account is a learning and communication platform and is not used for commercial purposes. If there is any infringement, please inform us in time and delete it after verification. The content is the author’s personal opinion and does not mean that this official account agrees with his/her views. This is for learning and reference purposes only, and no guarantee is made as to the accuracy, reliability or completeness of the information; contact/contribution cooperation: [email protected]